simmill 9W4

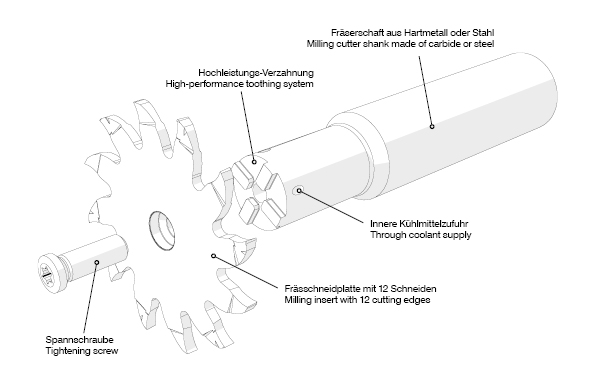

High-performance tool system with 12 cutting edges for groove and slot milling with milling depths up to 16.5 mm (0.650")!

The system consists of anti-vibration carbide and steel toolholders with internal coolant supply and milling inserts with 12 cutting edges with cutting widths from 0.5 mm (0.020") and up to 6.0 mm (0.236").

Thanks to high-performance toothing technology from Kaestner-Tools, torsion at the insert-holder interface is effectively counteracted and the insert sits very stably in the insert seat. This results in high torques and feeds are possible, a higher cutting performance is achieved and ultimately main times are reduced.

Milling inserts:

The milling inserts are available in cutting widths between 0.5 mm (0.020") and 6.0 mm (0.236") and are subdivided as follows:

- Well-proven cutting edge geometry for a wide range of applications, without corner radii, for cutting edge widths:

- 0.5 mm (0.020")

- 1.0 mm (0.039")

- GY geometry with staggered teeth with bilateral corner radii for smooth cuts and high surface qualities for cutting edge widths:

- 1.17 mm (0.046")

- 1.5 mm (0.059")

- 1.58 mm (0.061")

- 2.0 mm (0.079")

- 2.39 mm (0.094")

- 2.5 mm (0.098")

- 3.0 mm (0.118")

- 3.175 mm (0.125")

- GYY geometry with staggered teeth, a single-sided corner radius and an additional 45° chamfer for a division of the cut and thus less cutting pressure for cutting widths:

- 1.5 mm (0.059")

- 2.0 mm (0.079")

- 2.5 mm (0.098")

- 3.0 mm (0.118")

- 4.0 mm (0.157")

- 4.76 mm (0.187")

- 5.0 mm (0.197")

- 6.0 mm (0.236")

- Parting off milling with 6° parting off angle, with and without corner radii, for cutting widths:

- 1.0 mm (0.039")

- 1.5 mm (0.059")

- 2.0 mm (0.079")

Toolholder:

Carbide:

- With internal coolant supply and shank according to DIN 6535 HA

- shank diameters 15.875 mm (0.625") and 16.0 mm (0.630")

- L2 dimensions of 60.0 mm (2.362") / 90.0 mm (3.543") / 120.0 mm (4.724")

Steel:

- With internal coolant supply and shank according to DIN 1835 A

- shank diameter 19.05 (0.750") and 20.0 mm (0.787")

- L2 dimension of 32.0 mm (1.260")

The system details:

Video

Experience the tool system simmill 9W4 in a short video.

Further simmill product groups:

Modular tool system including cassettes for using the standard simturn product groups simturn AX and simturn DX as well as compatible adaptors for fine turning heads.