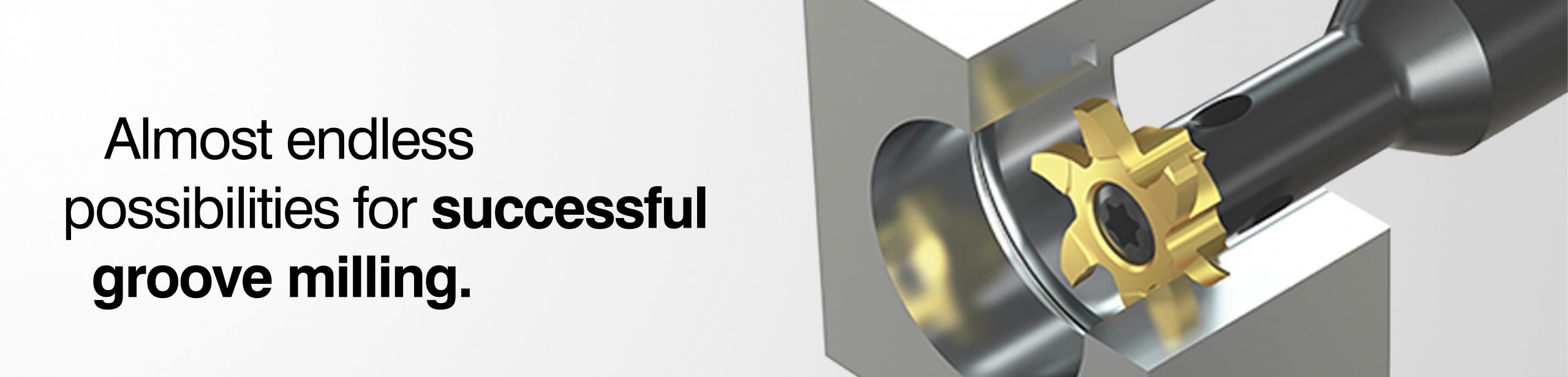

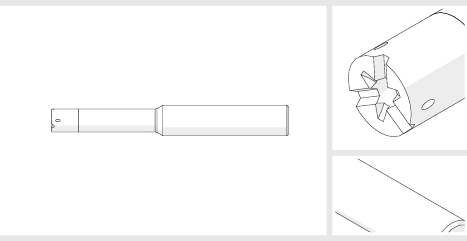

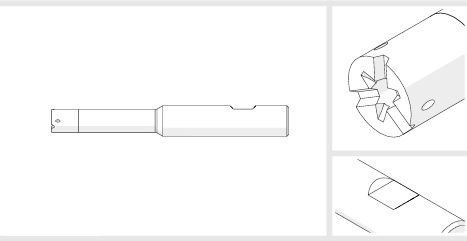

simmill PMX|PX|SX|UX|VX

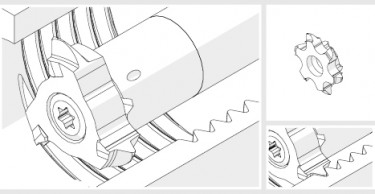

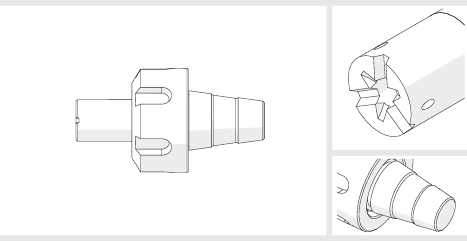

Extensive and wide spread range of indexable carbide milling inserts and carbide or heavymetal-milling cutter shanks with antivibration features. Milling inserts with three or six cutting edges for applications in bores between Ø 7,0 mm and Ø 40,0 mm. The insert seat is designed to provide optimal cutting force transmission as well as tight concentricity and axial-runout tolerances.

Main applications

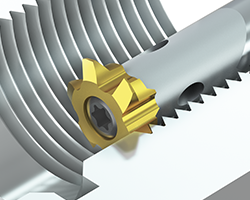

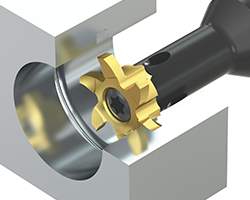

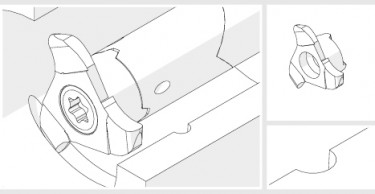

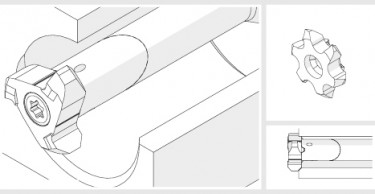

Circlip ring grooves

Chamfering

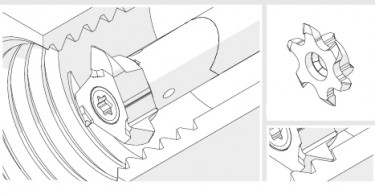

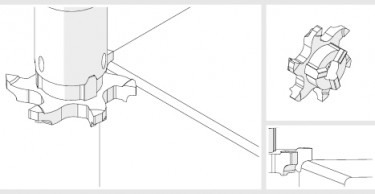

Thread milling

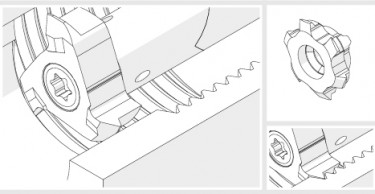

Groove milling

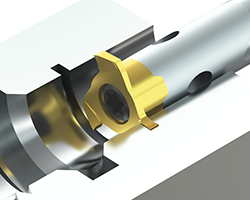

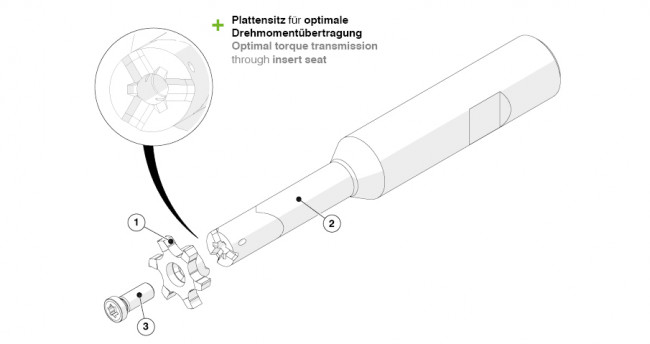

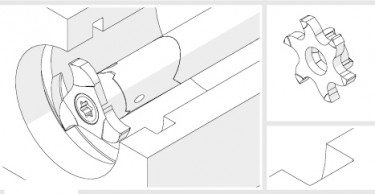

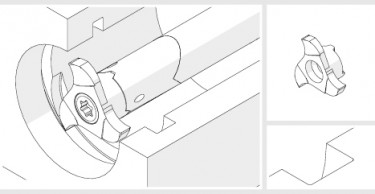

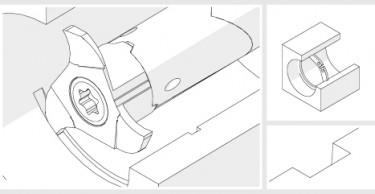

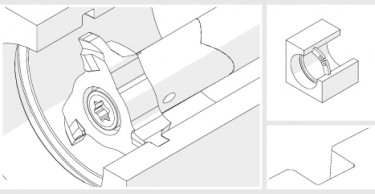

The system details:

1: High performance micro grain carbide milling inserts available with a wide range of coatings for every application.

2: Milling cutter shanks made of carbide or steel, mainly with through coolant supply and vibration-reducing insert.

3: Torx screw

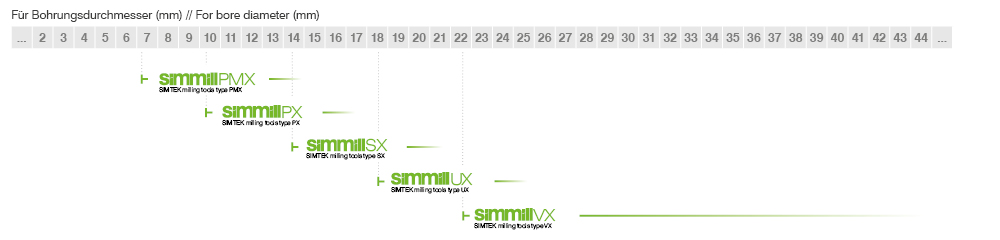

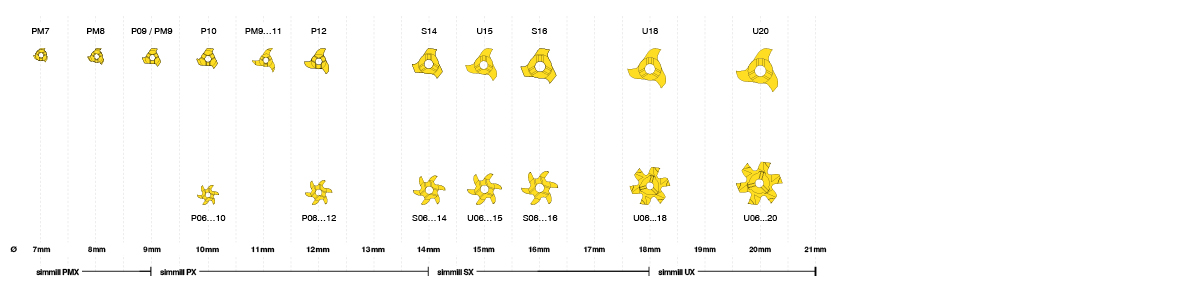

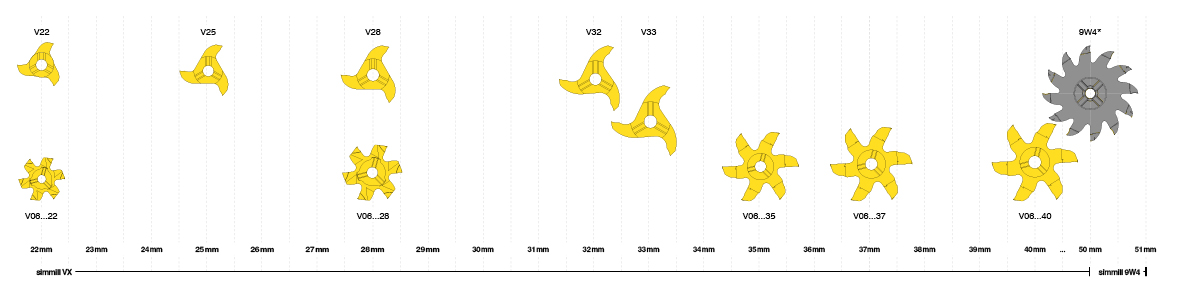

The sizes:

simmill PMX / PX / SX / UX with cutting diameters from 6,7 mm up to 19,7 mm.

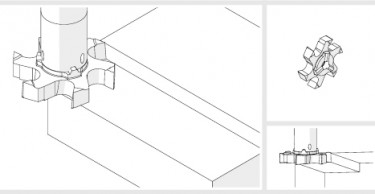

simmill VX and simmill 9W4 with cutting diameters from 21,7 mm up to 50,0 mm.

* The product group simmill 9W4 offers milling tools with a cutting diameter of 50,0 mm, 12 cutting edges and milling depths up to 16,5 mm for groove, slot and parting off milling. Click here to find out more!.

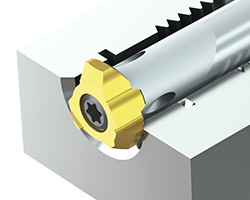

All standard applications:

General Groove Milling

General Groove Milling in light alloys

Circlip Ring Groove Milling

Circlip Ring Groove Milling with Chamfering

Full Radius Groove Milling

Thread Milling, Metric ISO-Thread, Partial Profile

Thread Milling, Metric ISO-Thread, Full Profile

Thread Milling, Whitworth Thread, Full Profile

Chamfering

Corner Rounding

Face Milling

Different types of toolholders for simmill PX/SX/UX/VX:

Solid Carbide and Steel Milling Cutter Shanks, Cylindrical (DIN 6535 HA)

Solid Carbide and Steel Milling Cutter Shanks, Weldon (DIN 6535 HB)

Milling Cutter Shank, for Collet Chucks (DIN 6499)

Further simmill product groups:

Modular tool system including cassettes for using the standard simturn product groups simturn AX and simturn DX as well as compatible adaptors for fine turning heads.