SIMTEK presents innovative milling tool system with monoblock performance features

Until now, users have had to choose between the flexibility of a modular tool system with interchangeable cutting inserts or the high precision and power transmission of monoblock tools. With the new simmill 9W family from SIMTEK, this decision is no longer necessary in most cases. The tools in this series offer interchangeable cutting inserts that come close to monoblock tools in terms of power transmission and precision - and at a significantly lower cost.

The starting point of the simmill 9W family, which is now available in different versions, is the simmill 9W4 tool milling system, which was originally developed for a complicated component in the automotive industry and represents a significant advancement in the field of milling tools. Norbert Seifermann, CEO at SIMTEK, emphasizes: "Many industrial customers want to take advantage of the flexibility of modular milling tools, but until now this was often associated with limitations in terms of accuracy and load capacity. With the simmill 9W4 system, we now offer a powerful solution for grooving, slot and parting off milling that makes this compromise superfluous in many cases."

Development and technical details

simmill 9W4 arose from a specific requirement in the automotive industry and is the result of intensive development work. For the production of a complicated component, a tool was needed that could work precisely and stably even under difficult conditions, such as limited space with long overhang lengths. To meet these requirements, the experts from Mössingen developed a milling tool that uses interchangeable cutting inserts and yet achieves almost the stability and precision of a monoblock tool.

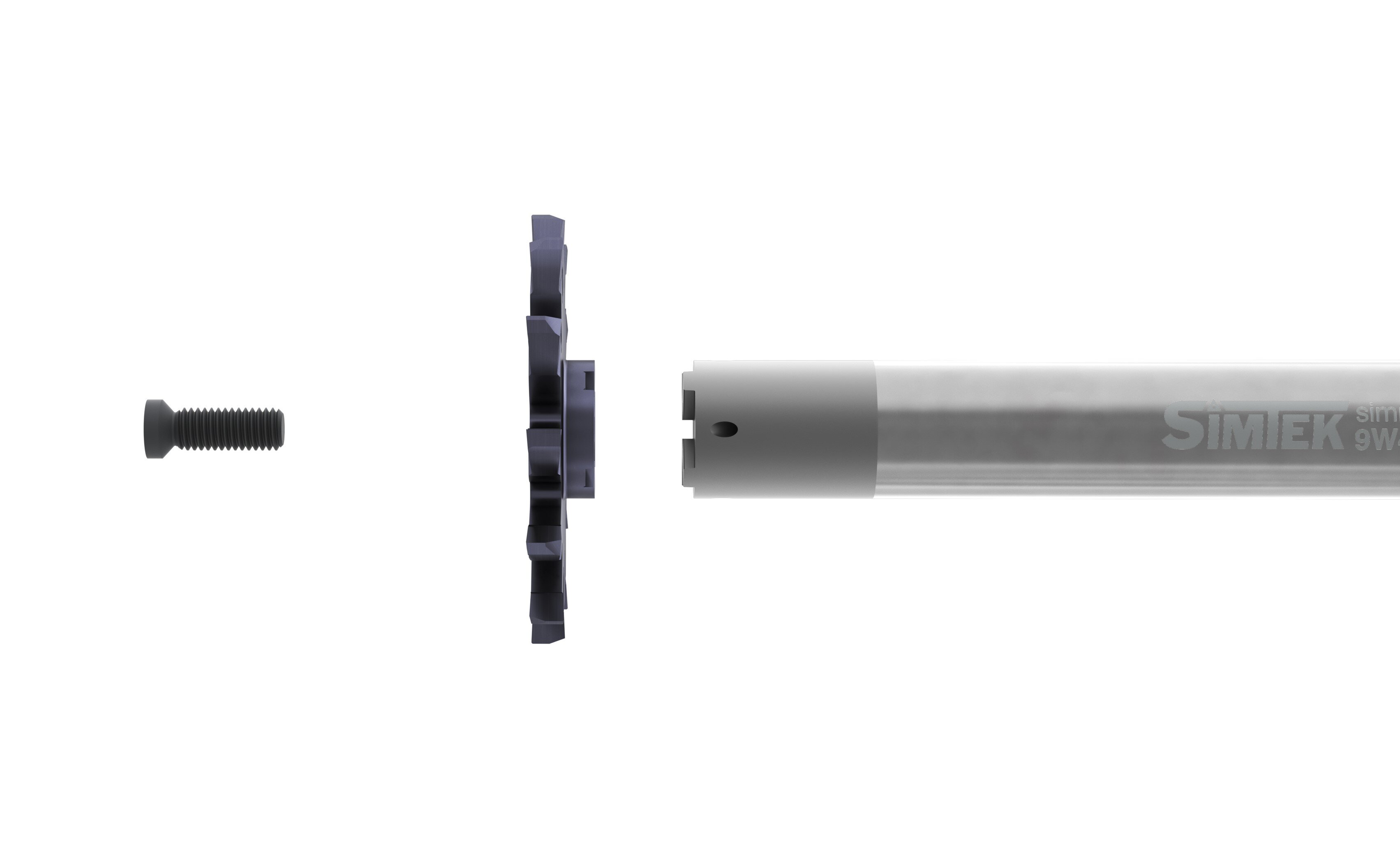

The simmill 9W4 system is based on a highly developed gearing technology that offers a number of advantages. The high stability of the gearing makes the simmill 9W4 system suitable for applications with high torques and, thanks to the ground gearing, ensures high precision in radial and axial run-out with minimal wear at the interface between the holder and cutting insert.

Advantages and possible applications

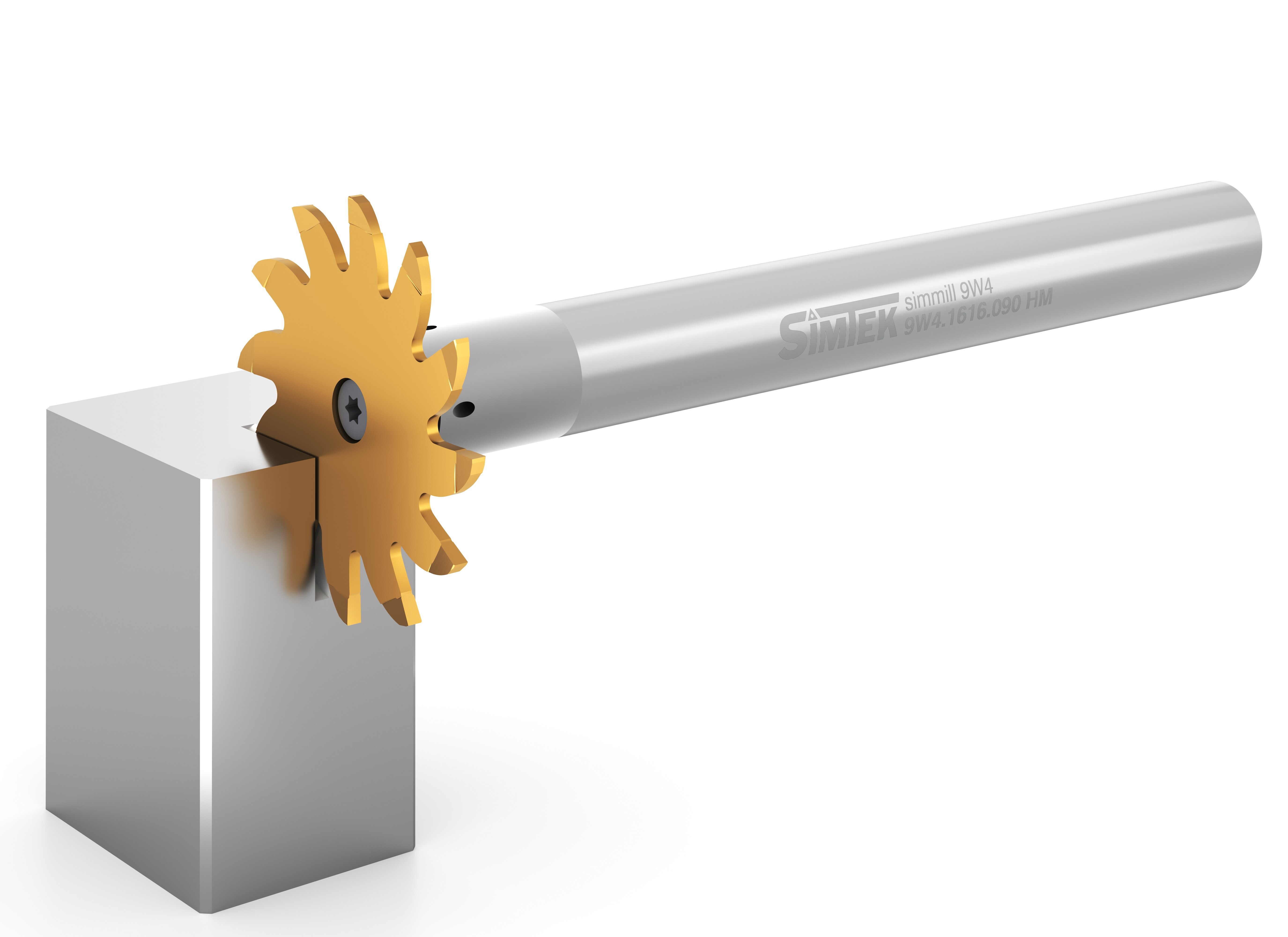

The standard range of the simmill 9W4 system is already suitable for milling depths of up to 16.5 mm, which expands its range of applications compared to many other tool solutions. The interchangeable cutting inserts are available in cutting widths from 0.5 mm to 6.0 mm. The 12 straight or cross-toothed cutting edges enable high cutting performance and therefore shorter main times.

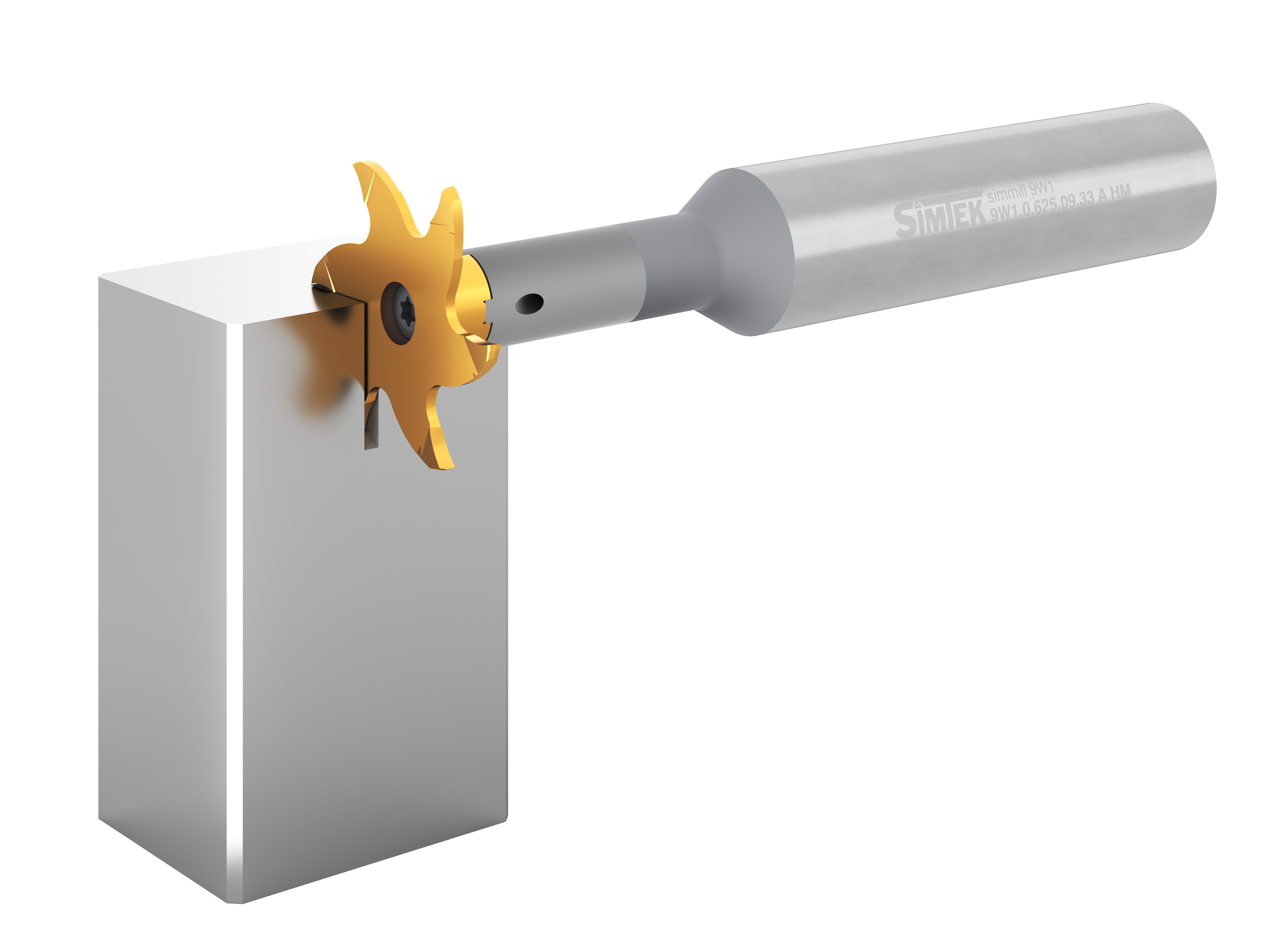

The system is also impressive when used in confined spaces: The shank diameter is up to three times smaller than the diameter of the cutting insert. The integrated coolant supply contributes to a longer tool life and ensures efficient cooling.

Durability and material efficiency

Another aspect that characterizes the tool system is its design, which is geared toward durability and material efficiency. The robust construction and replaceable cutting inserts help to extend the service life of the tools and reduce material consumption during operation. Thanks to the modular design of the system, only the cutting insert usually needs to be replaced when worn. Compared to completely replaced monoblock tools, this can help to use resources more sparingly and avoid waste. In addition, the precise connection between the toolholder and the cutting insert enables economical use of the components and can thus contribute to efficiency in production.

Variants and further developments

The simmill 9W4 milling tool system has been continuously developed since its introduction and now includes different variants with different diameters and cutting edge geometries. In addition to simmill 9W4, the 9W1 variant is currently available with a maximum milling depth of 9.3 mm and cutting widths of 1.2 mm to 2.5 mm. Steel and carbide holders are available for both variants. Numerous other versions and intermediate sizes are already being used successfully for customized solutions. "These further developments underline the flexibility of the system and its ability to close the gap between conventional interchangeable tools and monoblock tools," explains SIMTEK CEO Seifermann.

The simmill 9W4 tool milling system in detail

simmill 9W1 - This variant has 6 teeth and is designed for cutting depths of up to 9.3 mm.

simmill 9W4 - This variant has 12 teeth and is designed for cutting depths of up to 16.5 mm.

Contact us!

Our team will be happy to help you at any time.