Optimum machining conditions at any time, reducing non-productive time, avoiding 100% controls: there are many reasons to ensure optimum chip control in series production.

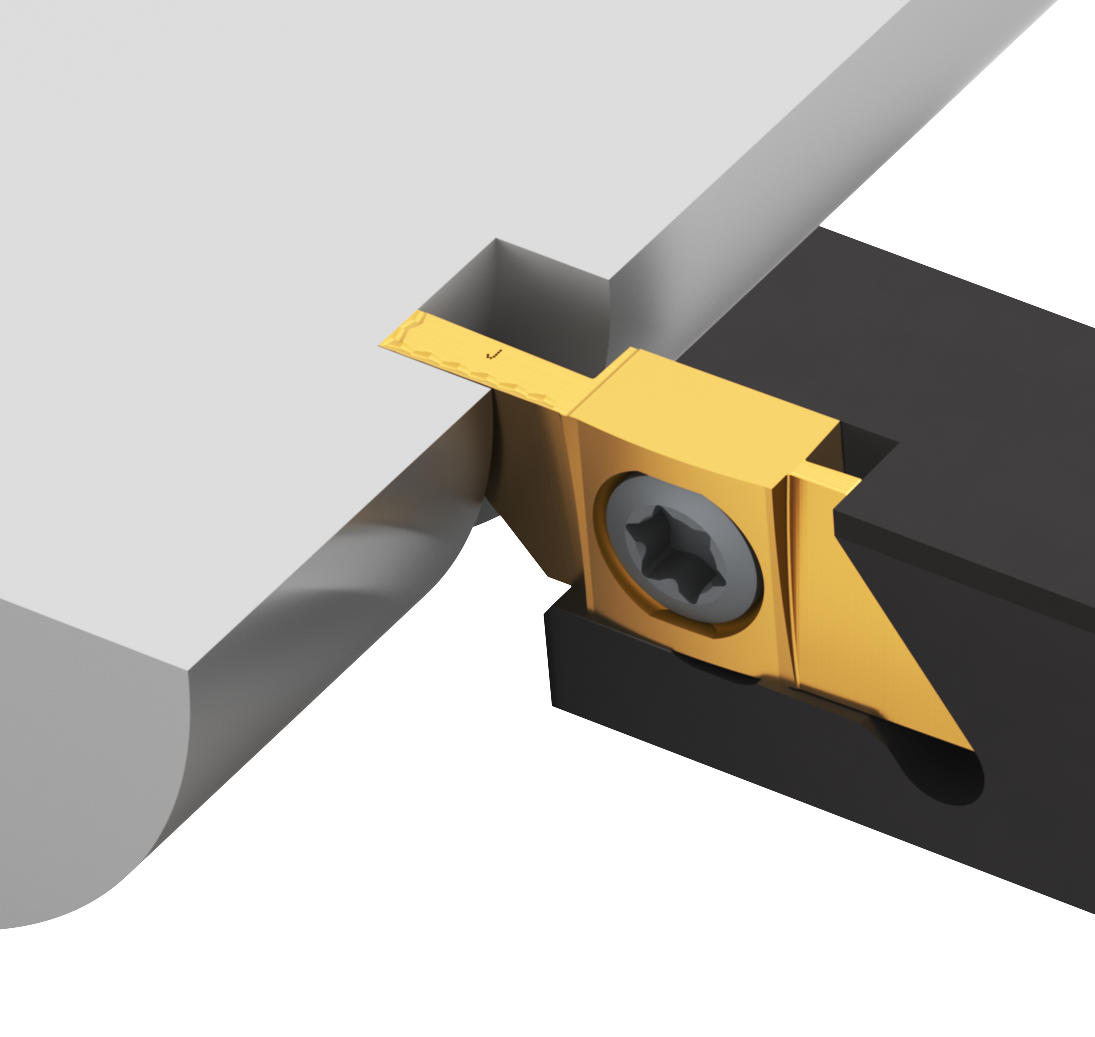

Lasered chip forming geometries enable maximum chip control and increase the process reliability and machining efficiency.

In addition to individual tooling solutions, SIMTEK also offers standard tools with 3D-lasered chip forming geomometry for the following applications:

Double-edged indexable cutting inserts for grooving and longitudinal turning

Triple-edged indexable inserts for grooving and profiling

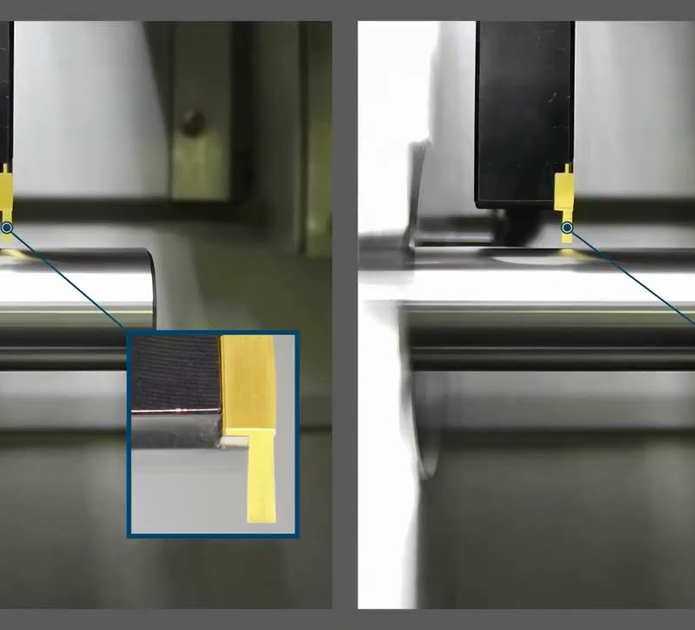

The video shows the benefits of tools with lasered chip forming geometries compared to conventional tools with a ground chip forming geometry.

In the video you see two different applications:

the first application shows grooving and longitudiinal turning while the second application shows grooving and profile turning with full radius.

Norbert Seifermann

CEO, SIMTEK AG

Contact us!

Our team will be happy to help you at any time.