Optimum machining conditions at any time, reducing non-productive time, avoiding 100% controls: there are many reasons to ensure optimum chip control in series production.

Lasered chip forming geometries enable maximum chip control and increase the process reliability and machining efficiency.

Our revolutionary system combines the best of two worlds. It combines the advantages of a monoblock tool with the cost-effectiveness of a modular tool system. This means maximum stability and precision – with complete flexibility.

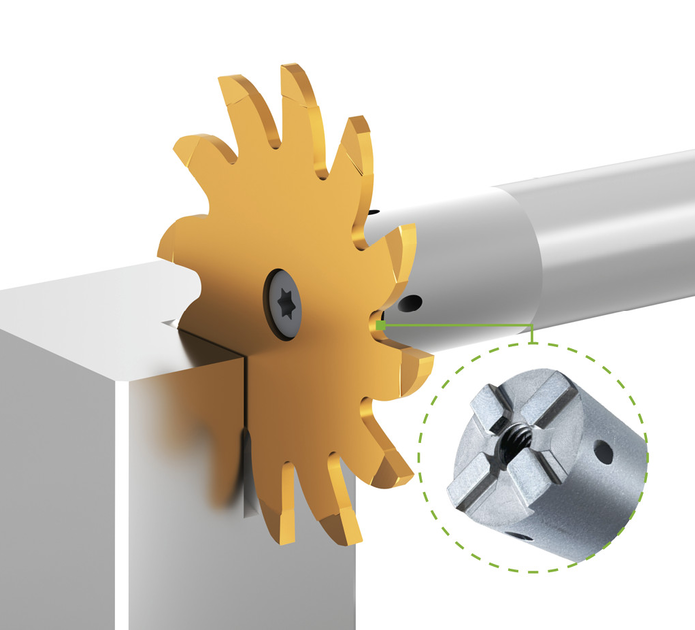

Discover simmill 9W, the robust system with up to 12 cutting edges for slotting, parting and slotting with milling depths of up to 16.5 mm!

Variability is one of the main success factors of any production. The ability to react quickly and at the same time cost-effectively to new requirements is therefore taking on an increasingly important role. With tools that can be used in variable lengths, SIMTEK offers you ideal solutions to meet these requierements.

At SIMTEK, a team of experienced tool designers works hard and with passion to develop the best possible tooling solution for each of your applications. The main focus is always on optimally designing the quality and performance features as well as achieving the best economic efficiency for you. This leads to the need to think beyond standard tools.

Contact us!

Our team will be happy to help you at any time.